Mastering current challenges such as energy costs and a shortage of skilled workers in a relaxed manner

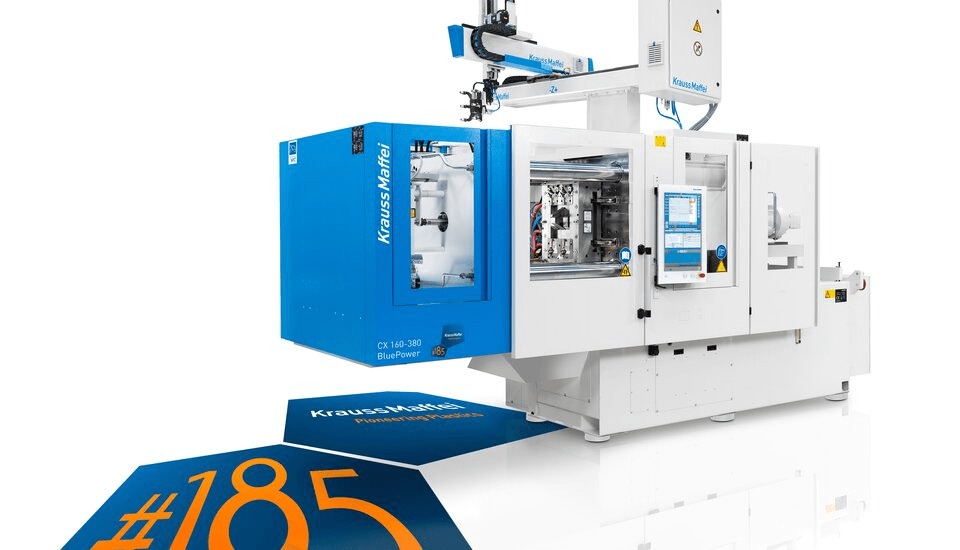

More energy efficiency? And less stress at the same time? On the occasion of the company’s 185th anniversary, KraussMaffei is offering a special edition of the popular CX series with attractive additional equipment that supports plastics processors with current pressing issues such as energy efficiency or the shortage of skilled workers.

The CX series is known for its flexibility, compact design and incredible versatility. The special edition with the suffix #185 comes with a package of attractive extras that normally cost money but are now available at no extra cost.

With the machines of the CX series, companies are also optimally positioned for unusual injection molding applications to increase sustainability. Whether sustainable coasters for coffee mugs made from biopolymers based on coffee groundsGebaplast in the Netherlands or fastening material for membranes in tunnel construction made from recycled sea plasticOldroydin Norway.

Especially with such at first glance unconventional production tasks, it is shown again and again how valuable the flexibility, compactness and efficiency of the CX series is in order to be able to achieve high reproducibility and high output rates with uncompromising quality.

Manuel von Varchmin

Director IMM Global Sales and Area Sales EMEA

With uncomplicated financing models, KraussMaffei shows that small machines don’t have to worry too much when it comes to financing. One of these options is the new “flexPay” model, which is offered in addition to the anniversary equipment package. Thanks to the pay-per-use logic, the rate is flexibly adjusted to the utilization of the machine, which means that in addition to the basic fee, the customer only pays for the machine capacity that is actually used. The customer therefore benefits from low financing costs with maximum flexibility.

With the special edition of the CX series, KraussMaffei now offers its customers even better efficiency and quality in injection molding applications and supports them in mastering current challenges with ease. Therefore, the motto of the anniversary offer is aptly “RelaCX – it’s a CX!”.