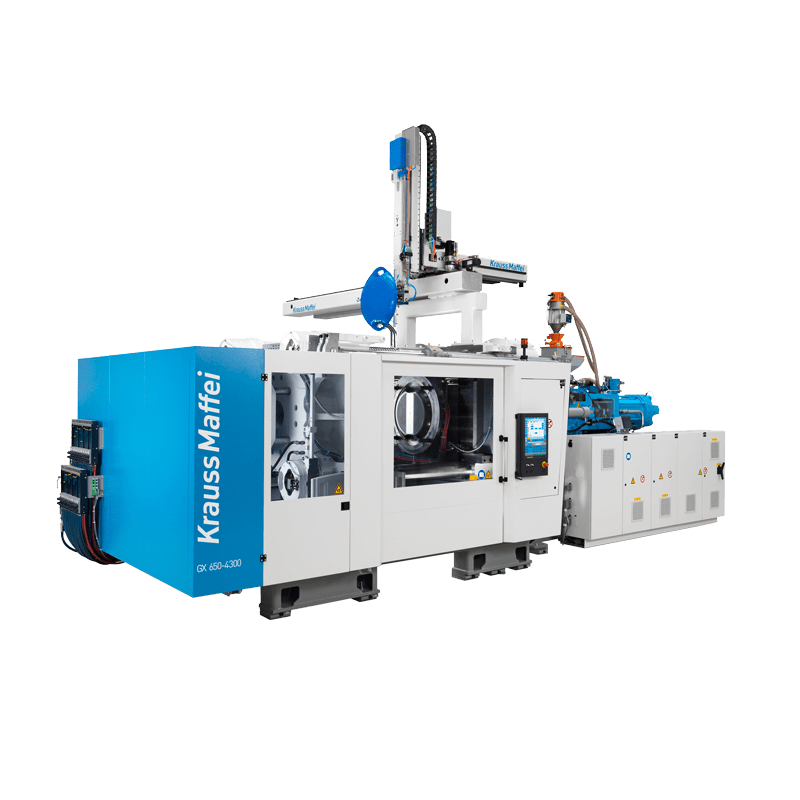

Powerful injection unit with proven plasticizing system

For maximum reproducibility with optimum melt quality

Maximum shot weight constancy with optimum reproducibility

Profit from unlimited precision – the proven in-line injection unit with its rotary piston design transmits the force centrally via the injection piston to the screw. This direct path ensures absolute precision and maximum reproducibility. Injection regulation of pressure and speed is a standard feature of the GX and guarantees you maximum process reliability.

High throughput with outstanding melt quality

Our plasticizing systems are characterized by their excellent melt quality and cover a wide range of applications for different plastics. The GX plasticizing system can be exchanged with other KraussMaffei series. Our many years of experience and technology expertise in coordinating complex processes during plasticizing ensure high melt specifications with corresponding throughputs and optimum melt quality. The right choice of melt system leads to improved quality of your products and higher value retention.

The right screw for every plastic

In order to provide an ideal solution for the processing demands with different polymers, we have developed materialand processing-specific plasticizing systems. In addition to outstanding melt quality and high throughputs, high-tech plastics mostly require additional wear resistance against adhesion, abrasion and corrosion in order to extend their service life. Depending on the part requirement, special plasticizing systems containing specific screws, check valves and cylinder fittings are available to you. Extract from our wide range of plasticizing solutions for processing:

– PC and PMMA materials,

– Short- and long-fiber-reinforced plastics,

– Blends,

– Thermosets and silicones

With our core competence, i.e. plasticizing, there are practically no limits to your material-specific requirements.

Transparent technology

A fascinating tour of the GX injection molding machine

Excellent dual platen technology

-Top quality and maximum productivity

GearX and GuideX product innovations

-For fast locking and high part quality

Optimum accessibility

-Short set-up times, easy maintenance

Ideal interaction between automation and machine

-Proven economical overall concept

New MC6 control system

-Simple and clear operation with Split Screen, Process Designer and Eco function

Flexibility through modularity

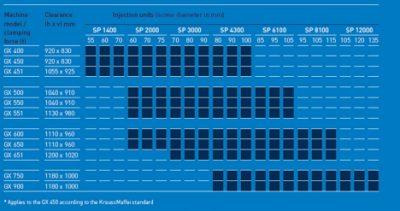

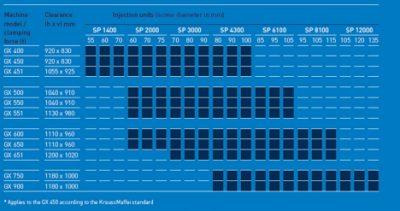

-Clamp, injector and drive unit can be individually combined

Powerful injection unit with proven plasticizing system

-Maximum reproducibility and high melt quality

Excellent dual platen technology

The powerful GuideX and GearX team ensures fast locking and excellent part quality

GuideX guide shoe – the intelligentmachine element for absolute platen parallelism with high force absorption.

As an intelligent fixed bearing joint with an optimized FEM design, the GuideX guide shoe is a genuine highlight in the GX series. Its stable design is the basis for the machine‘s outstanding platen parallelism. Thanks to the innovative technology, the greatly reduced forces are transmitted to the linear guides. This keeps the guides protected over the long term and maintains their precise ease of movement. The movements are optimal in terms of energy usage and the sensitive mold area protection can achieve its full effect.

Fast locking thanks to GearX

GearX locks the machine within the shortest possible time. The locking element is positively engaged in the tie bar notches via a short flux of force inside the unit. The enclosed locking unit is located behind the moving mold fixing platen and is permanently protected. Thanks to the optimized and no-frills design, accessibility to the ejection area remains habitually spacious and clear. Depending on the need, customer-specific ejector hole patterns, ejector plates, unscrewing units or rotary distributors can be placed flexibly behind the moving platen.

Discover our fiber composite solutions for advanced lightweight components:

KM_BR_Faserverbund_en

KM_BR_Werkzeuge_en