The injection unit – a masterpiece

Plasticizing systems are the heart of a machine and the core competence of KraussMaffei. They are distinguished in particularby their excellent shot weight consistency. This allows you to minimize your reject rate and produce the best quality products.

In-line injection unit

On the proven in-line injection units with a rotary piston design, the force is transferred centrally via the injection rotary pistons to the screw. Regulation is always high-resolution even at low pressures.

The CX Hybrid series

The CX Hybrid series combines the advantages of hydraulic and electric injection molding machine designs and ensures maximum reproducibility with its electric injection unit.

Ideal for high-precision requirements

The hydraulic clamping unit – clean and compact – in combination with the electric injection unit ensures a high performance level for parallel plasticizing and injection rates of up to 300 mm/s. The machine concept with cantilevered clamping unit makes high cleanroom classes possible. That makes them an efficient universal solution in the electronics and medical industries as well as for the production of sophisticated technical parts.

Attractive CX ClassiX machine package

The CX series is highly flexible and in conjunction with the ClassiX range is a cost-effective special version that satisfies all your requirements. At the same time, it offers the most comprehensive range of options for individual solutions for all industries.

Reduced investment with CX ClassiX

Shorter lead times and an attractive price: the ClassiX machine package combines the reliable technology of the CX series with absolute modularity and standardized options for maximum flexibility. Nearly all options from the extensive CX series catalog are available for this purpose. Choose your CX ClassiX from 160 basic machines with 450 basic combinations and a selection of another 500 possible options in proven KraussMaffei quality.

Transparent technology

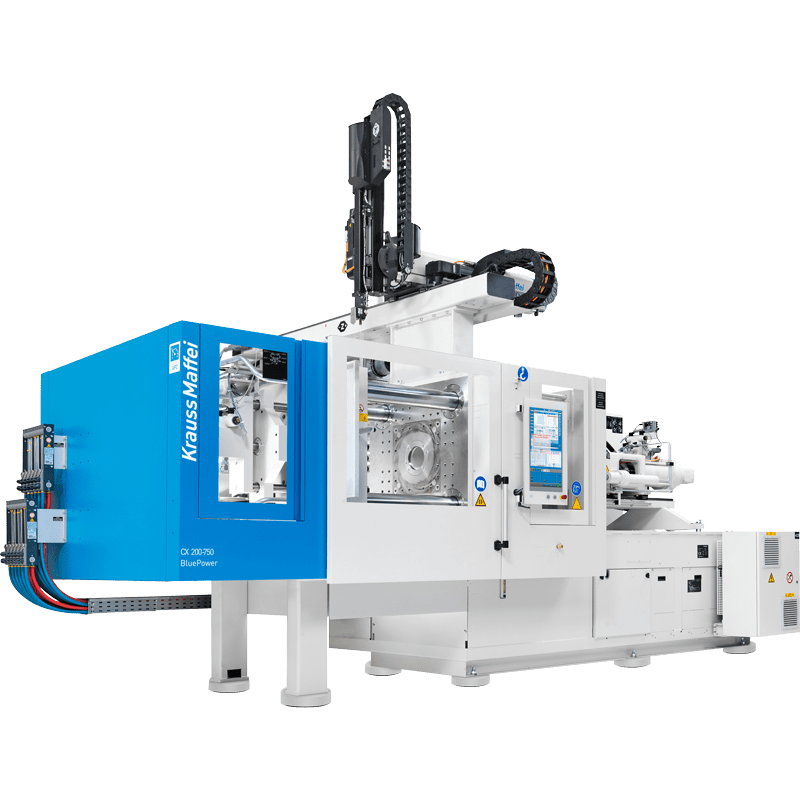

A fascinating tour of the CX

injection molding machine

Compact two-platen clamping unit

– Cantilevered (up to CX 160)

– Ultra-high precision

– Additional installation area

– Lubricant-free clamping unit

Fully integrated automation

– Space-saving and highly dynamic

– Integrated into control system

Unparalleled: APC plus

– Zero-defect production

– Perfect component quality

High-performance plasticizing unit

– Maximum reproducibility

– Constant melt quality

– In-line injection unit

BluePower solutions

– Vario Drive and Servo Drive save energy

– Intelligent energy management

Screwless cover

– Convenient and fast access to pump area

– Additional sound insulation

User-friendly MC6 control

– Perfect overview

– Intuitive – just 2 taps to the desired target

– Individual user interface

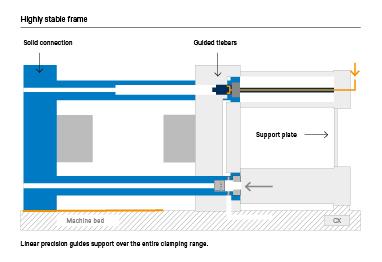

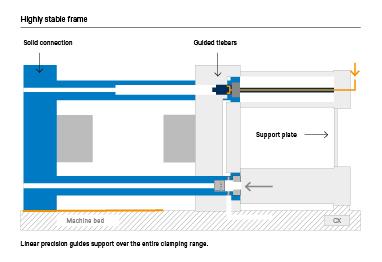

Proven two-platen technology

The clamping unit consists of a highly stable frame in box-type design. Forces are guided over the maximum possible distance. The four interconnected clamping cylinders guarantee a uniform distribution of forces. The result: extremely high mold weights can be used with absolute platen parallelism – no tilting, no misalignment.

Cantilevered clamping unit

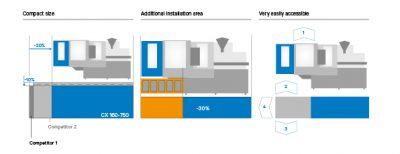

The clamping unit is cantilevered up to 1,600 kN, offering lots of space under the machine for additional peripheral equipment. Access to the conveyor belts is also ideal. A narrow support foot provides additional stability on larger injection molding machines.

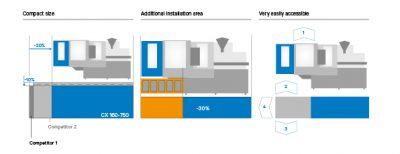

Compact design

Thanks to the two-platen technology developed by KraussMaffei, the CX is especially compact. Compared to other manufacturers, 10 to 20 percent of the area has been saved.

Proven two-platen technology

The clamping unit consists of a highly stable frame in box-type design. Forces are guided over the maximum possible distance. The four interconnected clamping cylinders guarantee a uniform distribution of forces. The result: extremely high mold weights can be used with absolute platen parallelism – no tilting, no misalignment.

Outstanding accessibility

From the nozzle to the ejector

Easy viewing and perfect accessibility. The large, transparent windows allow optimal viewing into the machine. The large doors in the safety housing can be completely folded back or slid open. All important areas are thus very easily accessible, greatly reducing set-up times.

More comfortable when working with the machine

The insulating mats in the pump area reduce the volume of the machine by 3 dB. For the human ear that means noise is reduced by half.

Discover our fiber composite solutions for advanced lightweight components:

KM_BR_Faserverbund_en

KM_BR_Werkzeuge_en